In the rapidly evolving world of technology, the Industrial Internet of Things (IIoT) has emerged as a transformative force, fundamentally reshaping the manufacturing landscape. For decades, factories have operated on established, often manual, processes. However, the integration of smart sensors, interconnected machines, and data analytics is paving the way for the “smart factory” of the future. This technological leap offers unprecedented opportunities for businesses to enhance productivity, reduce costs, and gain a competitive edge. This article delves into how IIoT is a game-changer, exploring its core principles, applications, and the tangible benefits it brings to the manufacturing industry. We will provide a comprehensive guide for anyone interested in understanding this revolutionary subject, from business leaders and engineers to students and policymakers.

What is Industrial IoT and How Does It Work?

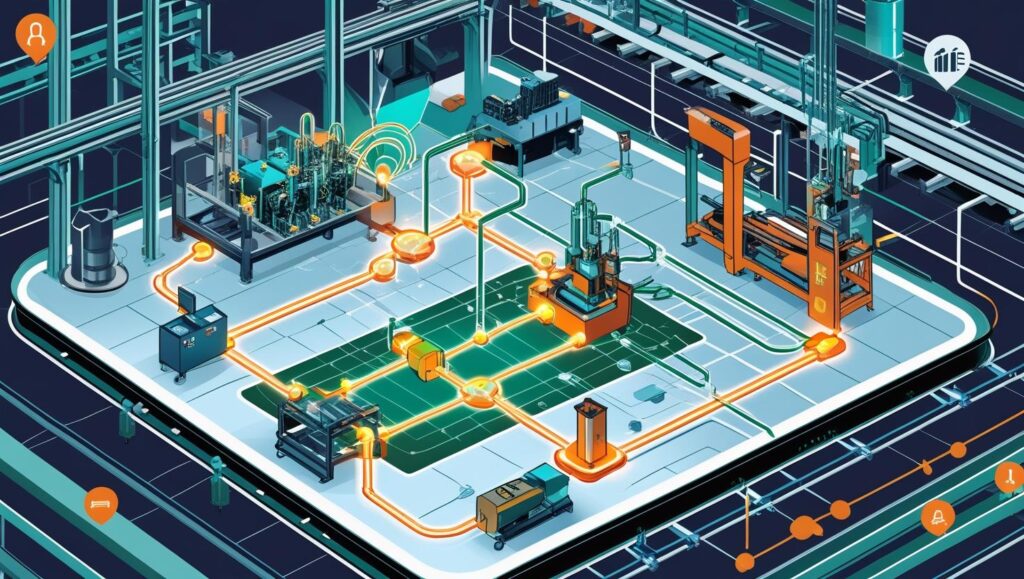

The Industrial Internet of Things is a subset of the IoT that focuses specifically on industrial applications. It involves the use of intelligent sensors, actuators, and connected devices to collect and analyze data from industrial machinery, processes, and environments. This data is then transmitted to a central system, often a cloud-based platform, where it can be analyzed to provide real-time insights. The niche of IIoT is its application in industrial settings, where precision, reliability, and security are paramount. Unlike consumer IoT, which might track personal fitness or control smart home devices, IIoT’s primary goal is to optimize operational efficiency and safety in a high-stakes environment. For example, a sensor on a manufacturing line might monitor temperature and vibration, alerting maintenance teams to potential issues before a catastrophic failure occurs. This predictive maintenance capability is a cornerstone of the subject of IIoT, moving beyond reactive fixes to proactive problem-solving. This process relies on a complex network of devices, data collection points, and analytical software, all working in concert to create a more intelligent and responsive operational system. The true power of IIoT lies not just in the data itself but in the ability to turn that data into actionable intelligence, enabling companies to make smarter, faster decisions.

Key Applications and Benefits of IIoT in Manufacturing

The practical applications of IIoT in manufacturing are vast and varied. One of the most significant areas is in enhancing operational efficiency. By continuously monitoring equipment, IIoT systems can provide insights into machine performance, energy consumption, and production bottlenecks. This enables managers to optimize workflows and reallocate resources more effectively. Another critical benefit is improved quality control. Sensors can detect minute deviations in production processes, ensuring that products meet strict quality standards and reducing waste. Furthermore, IIoT plays a crucial role in supply chain management. By tracking goods in real time, companies can gain a clearer picture of their inventory, predict demand more accurately, and streamline logistics. This level of visibility is particularly important for supply chain managers and production managers who need to make swift decisions to prevent delays. A case study of a large automotive manufacturer showed that implementing an IIoT system reduced machine downtime by 30% and increased overall equipment effectiveness (OEE) by 15%. This demonstrates the significant return on investment (ROI) that these technologies can offer. The ability to collect and analyze data at every stage of the manufacturing process gives businesses an unprecedented level of control and insight, helping them identify and address inefficiencies that were previously invisible. This holistic view of operations is a key driver of the IIoT revolution, making it a critical tool for any manufacturer seeking to stay competitive.

The Role of Data Analytics and Machine Learning in IIoT

Data is the lifeblood of any IIoT system, and advanced analytics are what make that data valuable. Raw data from sensors and devices is just a collection of numbers until it’s processed and interpreted. This is where machine learning comes in. By using machine learning algorithms, IIoT platforms can analyze vast datasets to identify patterns, predict outcomes, and even autonomously adjust processes. For example, an IIoT system in a food processing plant could use machine learning to predict when a piece of machinery is likely to fail based on historical performance data and current sensor readings. The system could then schedule a maintenance alert, preventing a costly and disruptive shutdown. This shift from reactive to predictive maintenance is one of the most powerful aspects of IIoT. Additionally, data analytics can be used to optimize energy consumption, helping businesses reduce their environmental footprint and save money. By analyzing energy usage patterns, an IIoT system can suggest or even automatically implement adjustments to lighting, heating, and machinery operation. The fusion of IIoT with machine learning is what truly creates a “smart” factory. These technologies allow for continuous improvement, as the system learns and adapts over time. The target_audiences for these solutions are broad, including not just engineers and IT professionals, but also management teams who are focused on long-term strategic planning and operational excellence. The insights generated by IIoT data analytics are not just for the factory floor; they can inform high-level business decisions, from product development to market strategy, making it a truly enterprise-wide solution. The seamless integration of these technologies creates a powerful feedback loop, where data from operations informs strategy, and strategic decisions are then implemented through automated or semi-automated processes, leading to a smarter, more agile organization.

Implementation Challenges and Future Outlook

Despite the immense potential, the journey to a fully connected smart factory is not without its challenges. One of the primary hurdles is the initial investment cost. Implementing IIoT systems requires significant capital for hardware, software, and training. Additionally, integrating new technology with existing legacy systems can be complex and time-consuming. Data security is another major concern. As more devices become interconnected, the attack surface for cyber threats expands. Protecting sensitive operational data and intellectual property is a top priority for any company embarking on an IIoT project. For these reasons, security experts and IT departments are integral to any successful implementation. However, the future of IIoT is incredibly promising. The cost of sensors and computing power is decreasing, making the technology more accessible to small and medium-sized enterprises. Furthermore, the development of 5G networks will provide the necessary bandwidth and low latency for real-time data transmission, unlocking even more advanced applications. The use of edge computing—processing data closer to where it is generated—will also reduce the reliance on cloud platforms, improving speed and security. As the technology matures, we can expect to see IIoT integrated with other emerging technologies, such as artificial intelligence and robotics, to create fully automated, self-optimizing factories. The long-term outlook for this subject is one of continued growth and innovation, making it an essential area of study for future engineers and entrepreneurs who want to shape the next generation of manufacturing. This is not just a passing trend; it is a fundamental shift in how goods are produced, and those who embrace it will be best positioned to succeed in the years to come.

Conclusion

The Industrial Internet of Things is more than just a buzzword; it is a powerful catalyst for a new era of manufacturing. By connecting physical assets with digital intelligence, IIoT is enabling businesses to achieve unprecedented levels of efficiency, quality, and safety. From predictive maintenance to real-time supply chain optimization, the benefits are clear and compelling. While the path to implementation has its challenges, the long-term rewards of embracing this technology are undeniable. The smart factory is no longer a futuristic concept but a tangible reality that is reshaping industries worldwide. This is why we created this detailed guide, aimed at providing a foundational understanding for everyone from executives to technical staff. By understanding and embracing IIoT, businesses can not only survive but thrive in the competitive global market.

Table: Comparison of Traditional vs. IIoT-Enabled Manufacturing

| Aspect | Traditional Manufacturing | IIoT-Enabled Manufacturing |

|---|---|---|

| Maintenance | Reactive (fixing after failure) | Predictive (preventing failure) |

| Data Collection | Manual, sporadic, and often incomplete | Automated, real-time, and comprehensive |

| Efficiency | Relies on human observation and limited data | Optimized through data-driven insights |

| Supply Chain | Limited visibility, manual tracking | Real-time tracking and predictive logistics |

Frequently Asked Questions

- What is the difference between IoT and IIoT? IoT (Internet of Things) is a broad term for connected devices in consumer and commercial settings. IIoT (Industrial IoT) is a specific subset focused on industrial applications like manufacturing, where data security, reliability, and precision are critical.

- Is IIoT only for large companies? While early adoption was seen in large corporations, the decreasing cost of technology and the availability of scalable solutions are making IIoT increasingly accessible for small and medium-sized enterprises (SMEs) as well.

- What are the main security risks with IIoT? Key risks include cyber-attacks that could disrupt production, data breaches exposing sensitive information, and vulnerabilities in legacy systems that are integrated into the network. Robust security protocols and continuous monitoring are essential to mitigate these risks.

Interesting Facts about Industrial IoT

- Analysts predict the global IIoT market will exceed $1 trillion by 2030, driven by increased adoption in manufacturing and other industrial sectors.

- Studies show that predictive maintenance, a core IIoT application, can reduce maintenance costs by up to 40% and unplanned downtime by up to 50%.

- The rise of IIoT is creating a demand for a new type of workforce with skills in data science, cybersecurity, and automation, highlighting the need for continuous education and upskilling.